Thermal Management--the Secret Of Packaging Technology Behind Uvcled

2021-04-16 17:32:31

In order to make UVC LED technology achievements better for mankind, a series of popular science articles on UVC LED packaging technology are specially launched to directly hit the technical threshold and share solutions, hoping to give industry colleagues more ideas and references, and jointly promote the orderly and healthy development of the industry , To provide more technical realization ways for human healthy life.

The continuous warming of UVC LED makes the market hot. Everyone knows that UVC LED has a significant sterilization and disinfection effect. Under a certain dose and distance, it only takes a few seconds to tens of seconds to kill common bacteria. But what everyone doesn't know is that with the hot market, various UVC LED application products on the market have emerged, many of which are shoddy. Often the same level of UVC LED products, the actual use effects are very different.

In the final analysis, it is the difference in technology and craftsmanship.

Let us start with the keyword thermal management and look at the secrets behind UVC LED packaging technology.

Thermal management, the key to improving the life of UVC LEDs

Like any electronic components, UVC LEDs are sensitive to heat.

The external quantum efficiency (EQE) of UVC LEDs is low. Of the input power, only about 1-3% is converted into light, and the remaining 97% is basically converted into heat. At this time, if the heat is not quickly removed and the LED chip is kept below its maximum operating temperature, it will directly affect the service life of the chip, or even it cannot be used. It can be said that thermal management is the key to improving the service life of UVC LEDs.

Do a good job in thermal management, select high thermal conductivity substrates

Due to the small size of UVC LEDs, most of the heat cannot be dissipated from the surface, so the back of the LED becomes the only way to effectively dissipate heat. At this time, how to do a good job of thermal management in the package joint is particularly important.

When it comes to thermal management in the packaging process, two aspects are indispensable, one is material, and the other is process.

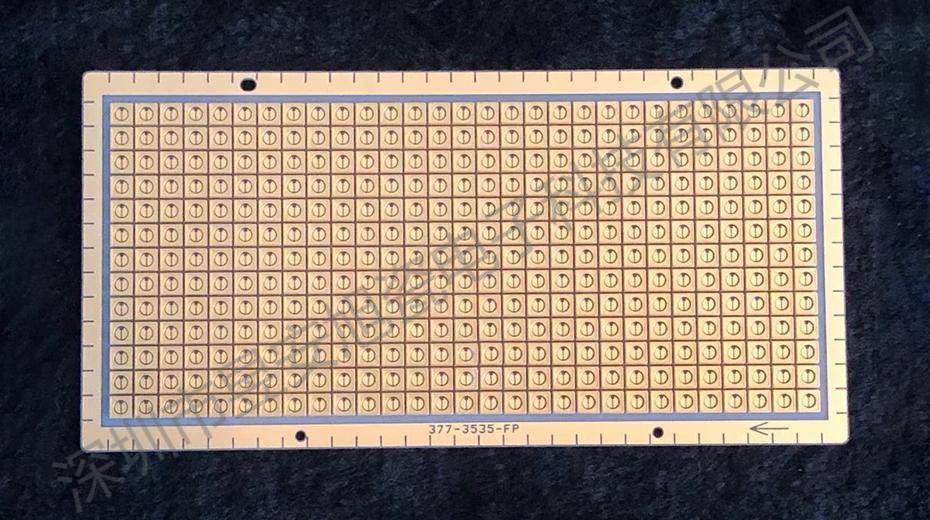

In terms of materials, after years of development, UVC LEDs currently on the market are basically based on flip-chip solutions with high thermal conductivity aluminum nitride substrates. Aluminum nitride (AIN) has excellent thermal conductivity (140W/mK-170W/mK), can withstand the aging of the ultraviolet light source itself, and meets the needs of high thermal management of UVC LEDs.

In terms of process, there are currently several die bonding methods on the market. The first is to use silver paste. Although this method has good binding force, it is easy to cause silver migration and cause device failure. The second method is to use solder paste soldering. In this method, since the melting point of the solder paste is only about 220 degrees, after the device is mounted, the re-melting phenomenon will occur after the device is mounted again, and the chip is easy to fall off and fail, which affects the reliability of the UVC LED. Therefore, the third type of die bonding method is mostly adopted on the market: using Au-Sn eutectic soldering. Compared with the first two die bonding methods, eutectic welding is mainly performed by flux, which can effectively improve the bonding strength of the chip and the substrate, and the thermal conductivity is more reliable, which is conducive to the quality control of UVC LEDs.

Since most of the UVC LED packaging materials and die bonding processes on the market are the same, why is the effect of thermal management so different?

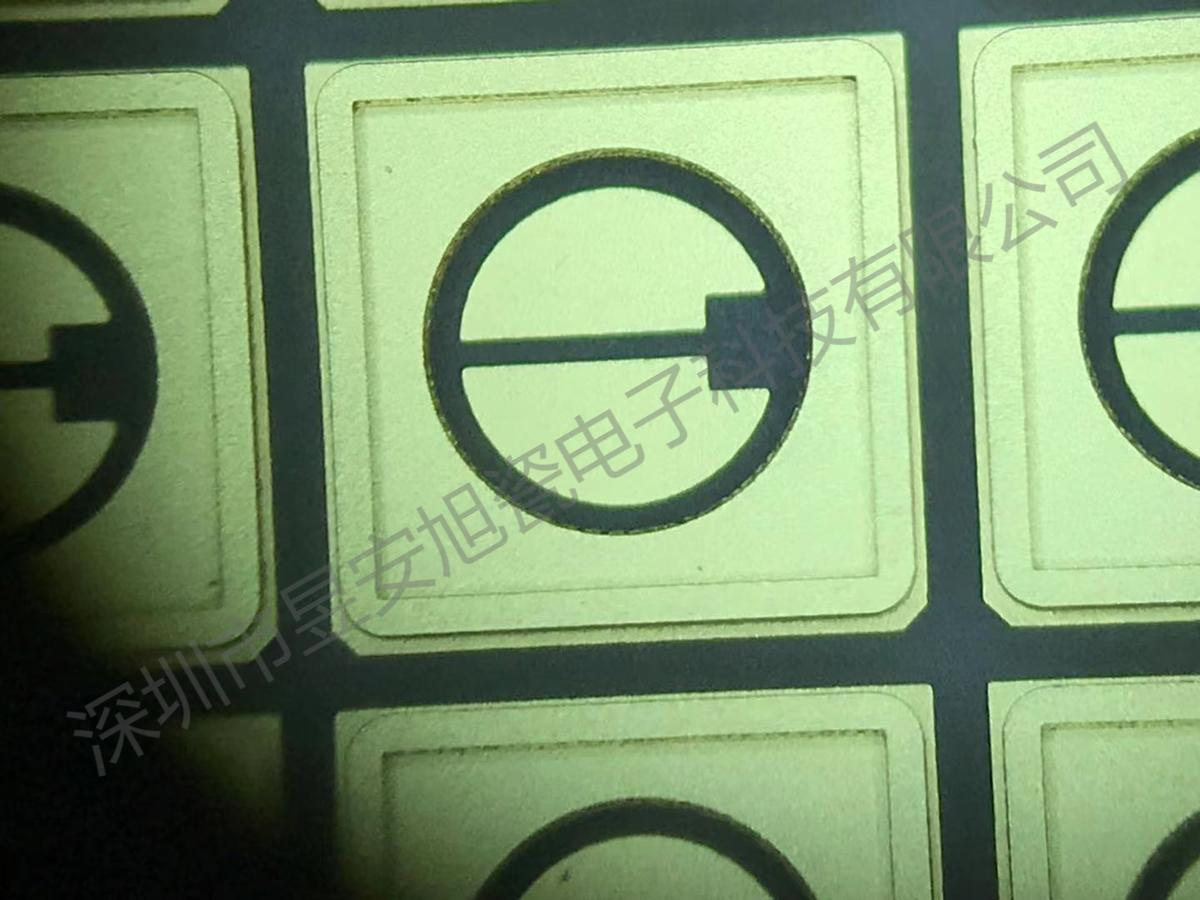

Reduce welding void rate

In simple terms, the soldering void rate refers to the welding process of the LED chip and the substrate. Due to the influence of the process, some areas cannot be soldered, and the defects formed are hollow in the shape, which is also an important indicator that affects heat dissipation.

In summary, thermal management is the key to improving the service life of UVC LEDs. Appropriate substrate materials and excellent packaging technology are indispensable. The high-performance aluminum nitride ceramic substrate that Yuan Xuci focuses on research can fully meet the needs of UVC LEDs for thermal management, and Yuan Xuci is also constantly studying the process and technology of packaging substrates, and is committed to launching more cost-effective products !