Application of aluminum nitride ceramic substrate in IGBT module

2021-04-28 19:19:45

IGBT module is composed of IGBT (Insulated Gate Bipolar transistor Chip) and FWD (Continuing Current Diode Chip) through a specific circuit bridging package of modular semiconductor products; The packaged IGBT module is directly used in frequency converter, UPS uninterruptible power supply and other equipment; IGBT module has the characteristics of energy saving, convenient installation and maintenance, stable heat dissipation, etc. The current market sales are more such modular products, generally referred to as IGBT IGBT module; With the promotion of the concept of energy conservation and environmental protection, such products will be seen more and more in the market. IGBT is the core device of energy conversion and transmission, commonly known as the "CPU" of power electronic devices. As a national strategic emerging industry, IGBT is widely used in rail transit, smart grid, aerospace, electric vehicles and new energy equipment and other fields.

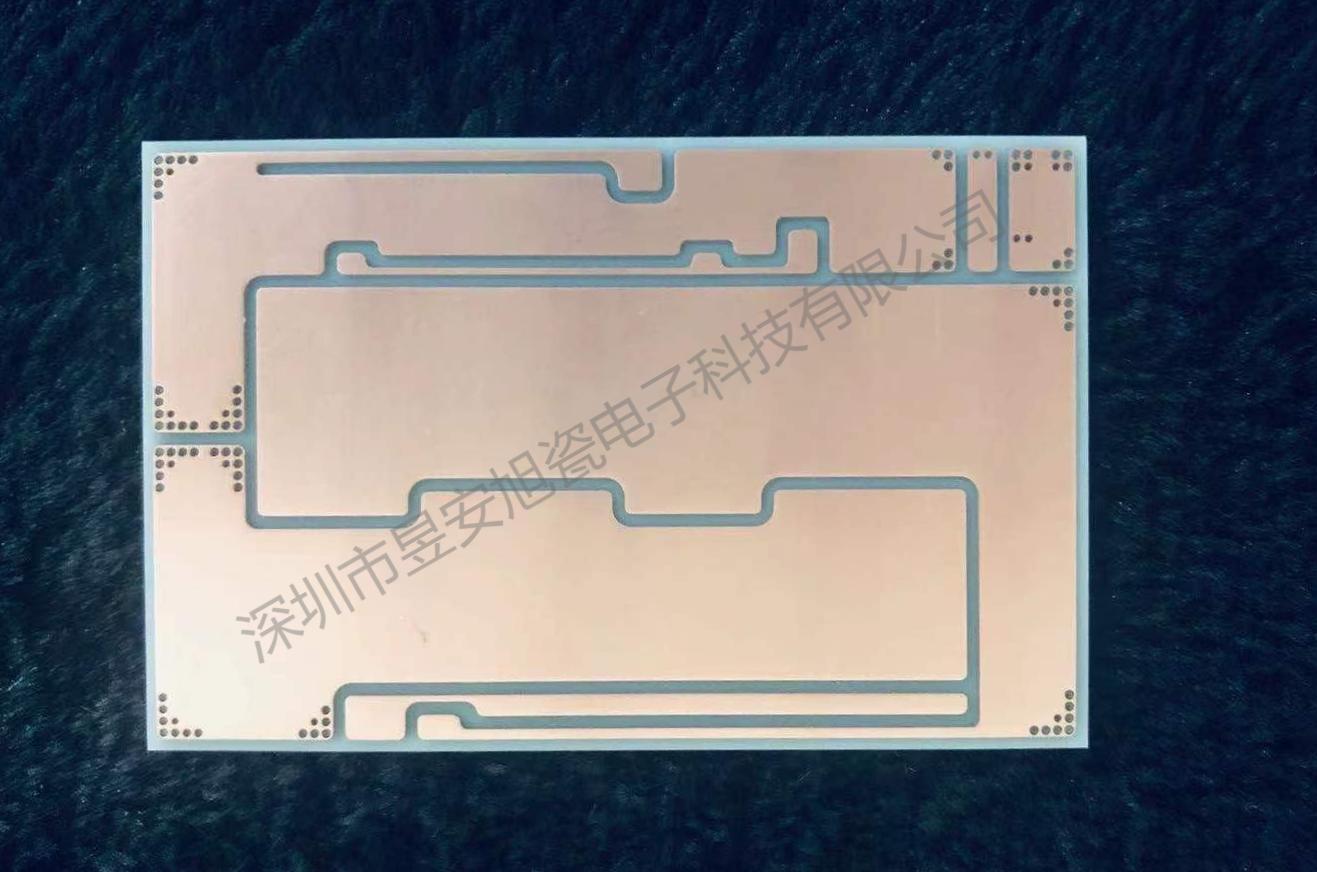

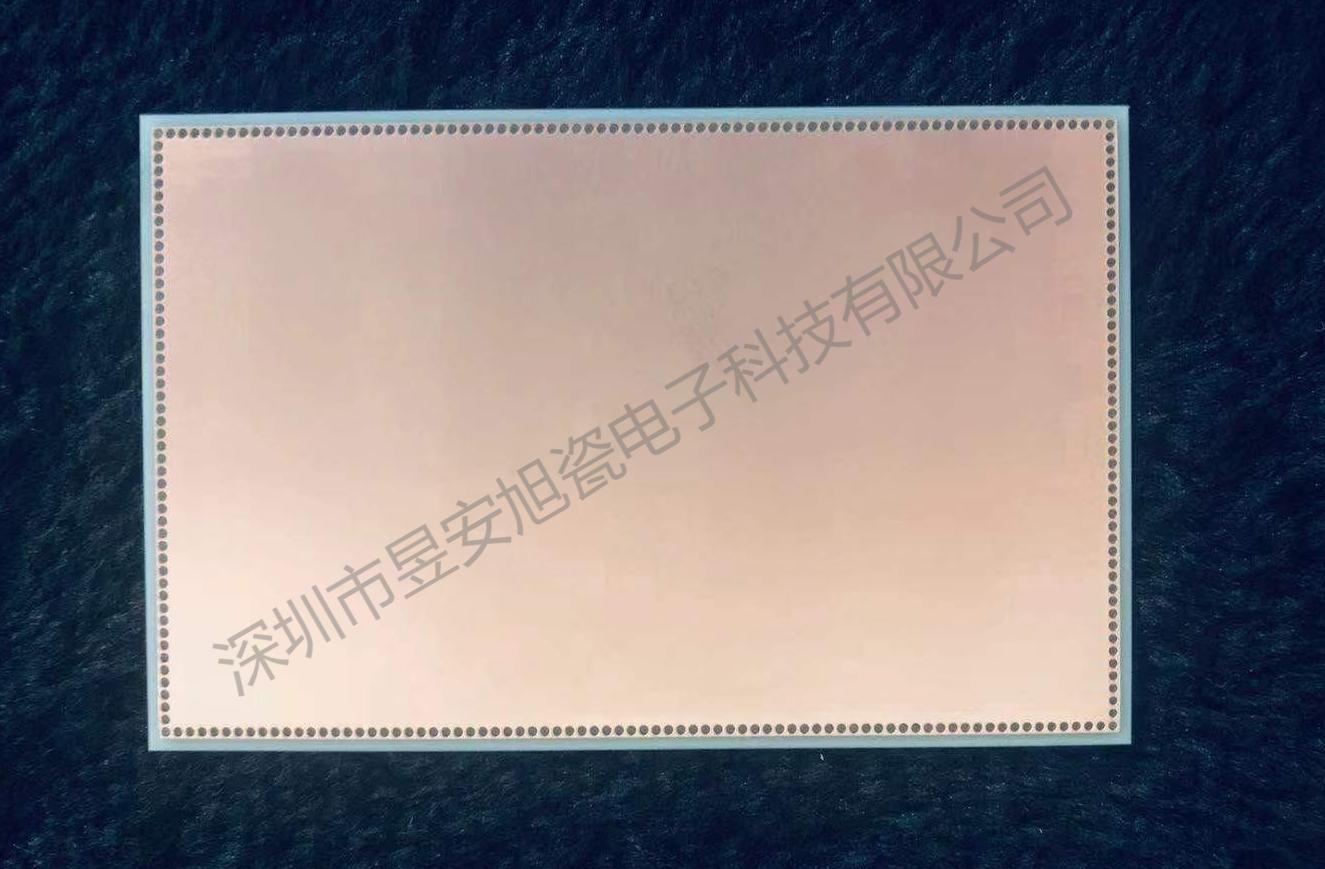

IGBT module because of their excellent electrical properties, has been widely used in modern power electronic technology, the design of the aluminum nitride ceramic substrate is one part of the IGBT module structure design, the merits of the ceramic substrate design will affect the electrical properties of modules, so want to finish the design of IGBT, good will need to follow some principles in the aluminum nitride ceramic substrate.

1. Characteristics of aluminum nitride ceramic substrate.。

Aluminum nitride ceramic substrate is mainly used as the carrier of various chips (IGBT chips, Diode chips, resistors, SiC chips, etc.) in the power electronics module technology. The ceramic substrate completes the connection of part of the chip's connection pole or connection surface through the surface of the copper layer, and its function is similar to that of PCB board. Aluminum nitride ceramic substrate has the remarkable characteristics of good insulation performance, good heat dissipation performance, low thermal resistance coefficient, matching coefficient of expansion, excellent mechanical properties, good welding performance. Using aluminum nitride ceramic substrate as the chip carrier, the chip can be separated from the heat dissipation base plate of the module, and the AlN ceramic layer in the middle of the substrate can effectively improve the insulation capacity of the module (the insulation voltage resistance of the ceramic layer > 2.5kV). And the aluminum nitride ceramic substrate has good thermal conductivity, the thermal conductivity can reach 170-260W/mK. During the operation of IGBT module, a large amount of heat will be generated on the surface of the chip, which will be transmitted to the heat dissipation bottom plate of the module through the ceramic substrate, and then transmitted to the radiator through the heat conduction silicone grease on the bottom plate to complete the overall heat dissipation flow of the module. At the same time, the expansion coefficient of aluminum nitride ceramic substrate is similar to silicon (silicon is the main material of the chip) (7.1ppm/K), will not cause stress damage to the chip, aluminum nitride ceramic substrate peeling resistance >20N/mm2, has excellent mechanical properties, corrosion resistance, not easy to deformation, can be used in a wide temperature range. Because of the excellent properties of aluminum nitride ceramic substrate, it is widely used in all types of IGBT modules. IGBT modules using aluminum nitride ceramic substrate have better thermal fatigue stability and higher integration degree.

2. Layout design

Engineering and technical personnel will be according to the design of high voltage, module structure characteristics, chip arrangement way to choose different size of substrate size grade, top and bottom copper layer edge distance ceramic layer edge distance to design reasonable, with A certain type of aluminum nitride ceramic substrate as an example, the edge of the copper layer and ceramic layer edge distance of A, A, should follow the principle of A acuity 0.5 mm + / - 0.3 mm, The design size is too small, does not conform to the reality, the manufacturer's technical ability usually can not meet, and when the size is too small, it may cause the discharge between the chip on the edge of the upper surface copper layer and the lower surface copper layer, reduce the module insulation voltage level, resulting in design failure. Landscape mainly according to the structural characteristics of the user module, chip configuration, thermal performance factors such as design, the aluminum nitride ceramic substrate in the process of landscape design, to meet the requirements, the need to pay attention to various substrate has a minimum line diameter and copper layer the minimum space requirements, minimum wire, copper layer minimum spacing is associated with the selected copper layer thickness, If the wire diameter is too small and the distance between copper layers is too small, the defects such as insufficient flow capacity of the substrate and insufficient insulation and voltage resistance of the device interval will be caused.

IGBT module has been widely used in modern power electronics technology, aluminum nitride ceramic substrate in power electronics module technology, as chip carrier. The merits and demerits of the ceramic substrate design directly affect the electrical performance of the module, follow certain design principles, reasonable layout design of the substrate, you can complete the excellent ceramic substrate design, so as to better complete the structure design of IGBT module.

Shenzhen Yu 'an Xuci Electronic Technology Co., Ltd. has been equipped with perfect production technology and product process flow in the production and design of aluminum nitride ceramic substrate, and has also launched mass substrate products in the application end of IGBT module products. In addition to aluminum nitride ceramic substrate for IGBT module application, Shenzhen Yu 'an Xuci Electronic Technology Co., Ltd. has also developed a variety of substrate sequence products including silicon nitride materials, which can meet the different performance requirements of the application end of the product