Application prospect of aluminum nitride substrate in automobile

2021-08-06 10:53:53

The automobile industry has undergone many changes under pressure from energy and environmental protection. Automobile from mechanization to electrification development, into the era of automobile electrical appliances. The transformation of the automobile industry has brought a lot of convenience to our travel life, among which aluminum nitride ceramic substrate plays a very good role and application.

Why is aluminum nitride ceramic substrate advantageous for automotive applications?

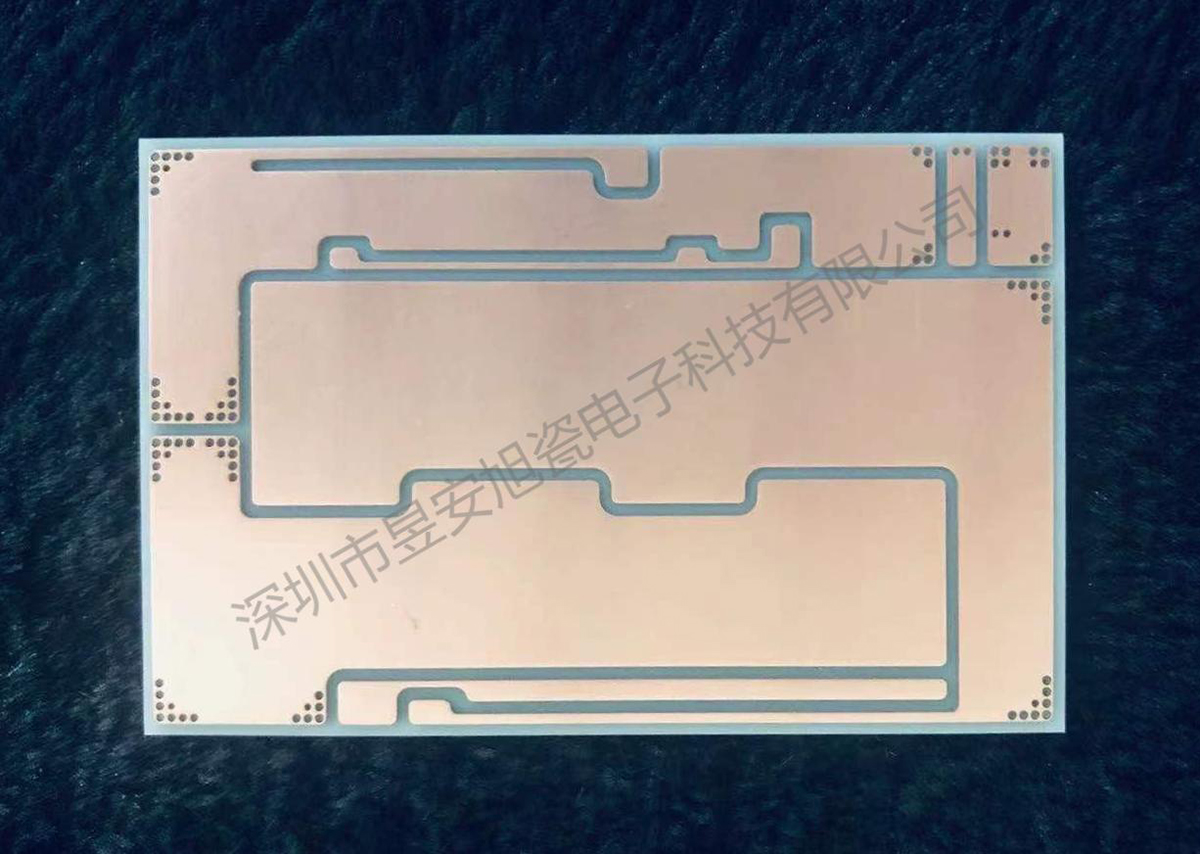

Integrated circuits need a large number of heat dissipation substrate

Aluminum nitride substrate has high thermal conductivity, non-toxic, corrosion resistance, high temperature resistance, good thermochemical stability and other characteristics. Aluminum nitrous ceramic substrate is an ideal packaging material, heat dissipation material, circuit components and interconnection carrier for large-scale integrated circuits, semiconductor module circuits and high power devices. At the same time, it is the best additive to improve the thermal conductivity and mechanical properties of polymer materials, which is widely used in new energy vehicles. With the increasing electronization of intelligent vehicles, the proportion of integrated circuits in the cost will be higher and higher, expanding the application scenarios and requirements of aluminum nitride substrate.

Graph from network

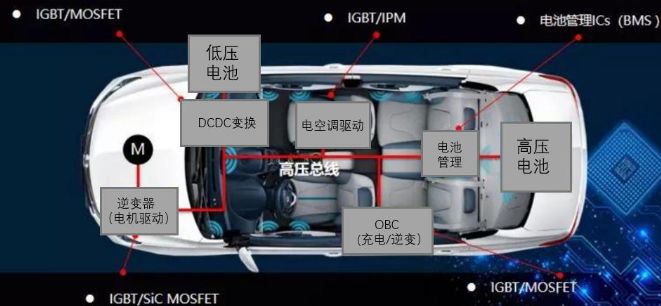

Two, the cost of 7%-10% IGBT requires a large amount of aluminum nitride substrate

In traditional IGBT module, alumina precision ceramic substrate is the most commonly used precision ceramic substrate. However, due to the relatively low thermal conductivity of alumina precision ceramic substrate and poor match with the thermal expansion coefficient of silicon, it is not suitable for high power module packaging material.

Aluminum nitride precision ceramic substrate has very high thermal conductivity and fast heat dissipation in terms of thermal characteristics. In terms of stress, the thermal expansion coefficient is close to that of silicon, and the internal stress of the whole module is low. Moreover, it has the high conductivity and excellent weldability of oxygen-free copper, which is the key basic material for IGBT module packaging. Improves the reliability of the high-voltage IGBT module. These excellent properties make the ALUMinized copper nitrides the preferred packaging option for high pressure IGBT modules.

Ceramic substrate for automobile LED headlights

Graph from network

Why aluminum nitride ceramic substrate? Because the operating temperature of LED headlights is very high. The brightness and power are linked, the greater the power, the higher the temperature, again to improve the brightness only through fine cooling design or heat dissipation device increase, but the effect is not ideal. Only aluminum nitride ceramic substrate can achieve the ideal effect. First of all, the thermal conductivity of aluminum nitride ceramic substrate is very high. Aluminum nitride substrate can reach 170-260W/mK, which is one hundred times that of aluminum substrate. Secondly, aluminum nitride ceramic substrate has very good insulation, and lamp beads more matching thermal expansion technology and a series of advantages.

In 2015, electric/hybrid vehicles accounted for 30% of the total power module market. By 2021, that share is expected to grow to 50 percent, representing a $2.3 billion market and 13 million vehicle sales. Power electronics technology is developing according to the demand of automobile market.

The market for power electronics used in electric and hybrid vehicles is expected to reach $13 billion in 2021. The technical and commercial opportunities of alN ceramic substrates for power device modules are promising.

reference

The article is from Aibang Ceramics.