Advantages of DPC aluminum nitride ceramic substrate in VCSEL packaging

2021-10-11 08:49:34

The full name of VCSEL laser is vertical resonant cavity surface emitting laser, referred to as surface emitting laser. It is a kind of semiconductor laser based on gallium arsenide semiconductor material.

In the field of application, iPhoneX is most familiar with using VCSEL as 3Dsensing light source device. Since then, VCSEL has opened the door of application in consumer electronics products. In automotive, VCSEL's solid-state lidar has higher reliability, stability and miniaturization, laying a foundation for large-scale application of lidar in automotive field. Others include commercial applications such as industrial heating, environmental monitoring, medical equipment and consumer applications such as 3D perception.

VCSEL chip power conversion efficiency is low, which means that there are certainly problems in heat dissipation, facing the problem of thermoelectric separation, and ceramic substrate is born to solve the thermoelectric separation.

VCSEL generates large heat when running. One is that the heat needs to be emitted through the substrate in time; Secondly, the power density of VCSEL chip is very high, so the stress caused by the thermal expansion mismatch between the chip and the substrate needs to be considered. Therefore, the realization of efficient heat dissipation, thermoelectric separation and thermal expansion coefficient matching has become an important consideration in the selection of VCSEL component packaging substrate.

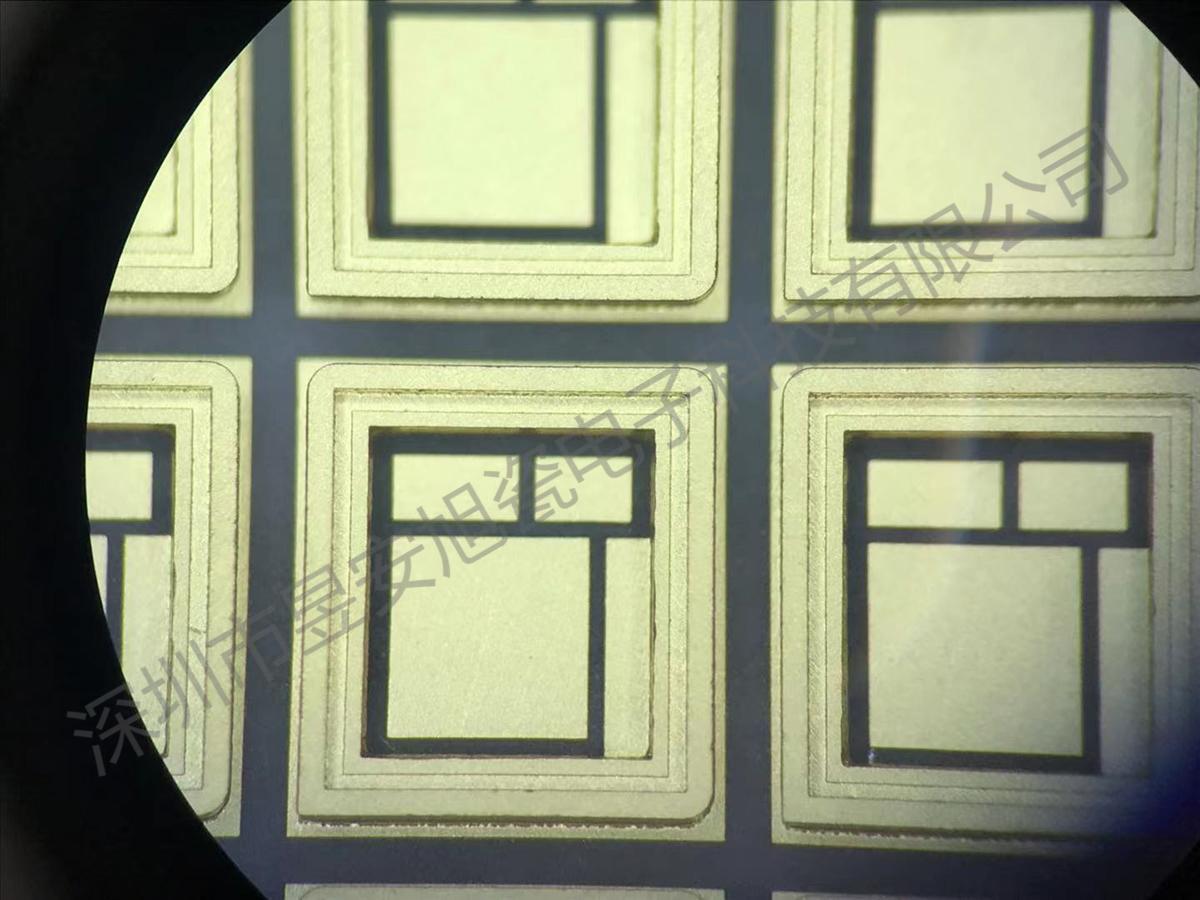

Direct copper plated ceramic substrate DPC ceramic substrate can meet the encapsulation requirements of VCSEL components. DPC ceramic substrate has many characteristics, such as high thermal conductivity, high insulation, high circuit accuracy, high surface flatness and thermal expansion coefficient matching with chip, etc., which rapidly occupies an important position in high power VCSEL component packaging. Because of the vertical structure of VCSEL, DPC ceramic circuit board has unique technical advantages such as high resolution, high flatness and high reliable vertical interconnection, which is more suitable for its vertical eutectic welding.

At the end of July 2021, the global VCSEL market is expected to grow from $1.2 billion in 2021 to $2.4 billion in 2026, with a cagR of 13.6% over the period, according to Yole estimates.

Ceramic substrate as VCSEL packaging substrate, its importance is self-evident. The growth of DPC aluminum nitride ceramic substrate in this field is very considerable.