High power LED heat dissipation new breakthrough - ceramic COB technology packaging process

2021-11-03 09:37:45

LED packaging is made by connecting the crystal (Die) with the wire, eutectic or coating packaging technology and the heat dissipation support Submount(sub-adhesive technology), and then connecting the chip on the system board to form the lamp source module.

Currently, LED packaging methods can be roughly divided into lens-type and Reflector type, where the Lens can be molded or Lens bonding, while the Reflector chip is mostly made of mixing, dispensing and packaging. In recent years, epitritic, solid crystal and packaging design gradually mature, LED grain size and structure of small year by year, high power single particle power up to 1 3W, its is more than 3W, when the LED power continues to improve, for LED grain load plate and system circuit version of heat dissipation and heat resistance requirements, it is increasingly stringent. In view of the comprehensive consideration of insulation, pressure resistance, heat dissipation and heat resistance, ceramic scaffolds have become one of the important materials for grain subadhesive technology. The technology can be divided into Thick film process (Thick film), low temperature co-firing process (LTCC) and film process (DPC). However, thick film process and low-temperature firing process, is the use of screen printing technology and the high temperature process of sintering, easy to produce rough lines, registration is not accurate, the contraction ratio, if in view of the high power LED product line more refined, or require registration accurate eutectic or flip chip process in terms of production of LED products, thick film with low temperature co-firing ceramic bracket, Has been gradually inadequate use.

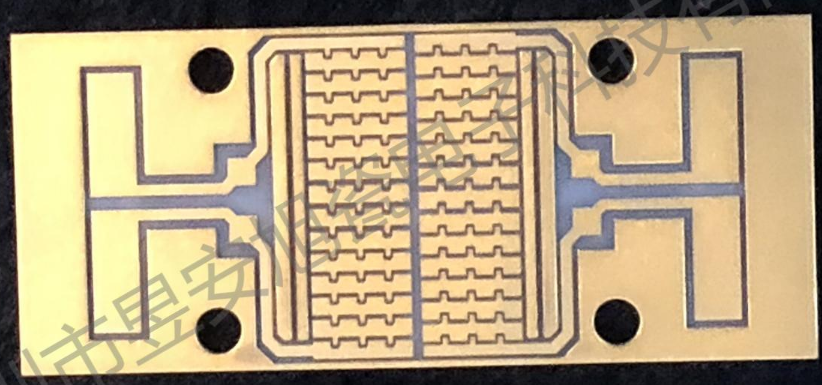

Metal circuit precision, material system stability and other characteristics, suitable for high power, small size, high brightness LED development trend, but also to solve the eutectic/coating packaging process of ceramic support metal circuit resolution and precision requirements. In addition to the production of thin film ceramic cooling bracket, Yu Anxu Ceramic Electronic Technology Co., Ltd. also developed a thin film ceramic COB(Chip On Board) cooling bracket to meet different lighting requirements.

When LED grains are used as the carrier, the heat dissipation bottleneck of the LED module is transferred to the system circuit board, which transfers heat from the LED chip to the heat dissipation fin and the atmosphere. With the gradual improvement of LED grain function, the material is gradually changed from FR4 to metal core printed circuit support (MCPCB). However, with the development of the demand for high-power LED, the heat dissipation coefficient of MCPCB material (2~4W/ MK) cannot be used for products with higher power. Therefore, the demand for Ceramic Circuit board (Ceramic Circuit board) is gradually popularized.

In order to ensure the material stability and optical decay stability of LED products under high power operation, the trend of ceramic as heat dissipation and metal wiring support has become increasingly clear. At present, the cost of ceramic materials is higher than that of MCPCB. Therefore, how to make use of the characteristics of ceramic high heat dissipation coefficient to save the material area and reduce the production cost has become an important indicator of the development of ceramic LED. Therefore, in recent years, the integration of multi-product packaging and system circuit based on ceramic material COB has been gradually paid attention to by various packaging and system manufacturers.

COB is not a new technology in the electronics manufacturing industry. It refers to directly sticking bare wafers on the circuit board, and welding the wires/welding wires directly on the gold-plated circuit board of PCB. It is also commonly known as Wire bonding. In the LED industry, modern scientific and technological products pay more and more attention to thinness and high portability. In addition, in order to save the space problem of the system board with multiple LED chips, in the demand of high power LED system, we developed the COB technology that directly pastes particles on the system board.

The advantage of COB is: high cost efficiency, simple circuit design, saving system board space, but there is also grain integration brightness, color temperature harmonization and system integration technology. Take 25W LED) as an example, the traditional high power 25W LED light source must adopt 25 1W LED pieces into 25 LED components, while COB fashion is to fashion 25 1W LED pieces into a single piece, Therefore, the required secondary optical lens will be reduced from 25 to 1, which is helpful to reduce the area of the light source, reduce the cost of materials and system, thus simplifying the secondary optical design of the light source system and saving the labor cost of assembly. In addition, the high-power COB package only needs a single high-power LED to replace multiple LED packages of more than 1 watt (including), which makes the product thinner and smaller. At present, the production of COB products is still dominated by MCPCB supports. However, there are still many problems of MCPCB heat dissipation and large area of light source to be solved, so the fundamental way is to update the heat dissipation material to the most effective solution. The ceramic COB support developed and produced by Yu anxu Porcelain Electronic Technology Co., Ltd. has the following advantages :1. Thin film process, make the basic circuit more accurate :(2) large volume to reduce the cost; (3) high reconfigurable, can be designed according to the different needs of partners.

The development of COB is a trend to simplify the system board, and the practicality, brightness, heat dissipation and cost control of lighting fixtures are important key factors. ICP in addition to provide a variety of thin film cooling bracket for single chip packaging, but also provides independent development of thin film line COB bracket, for different high power uses of users, and its more flexible choice, in order to look forward to LED lighting soon become more popular.