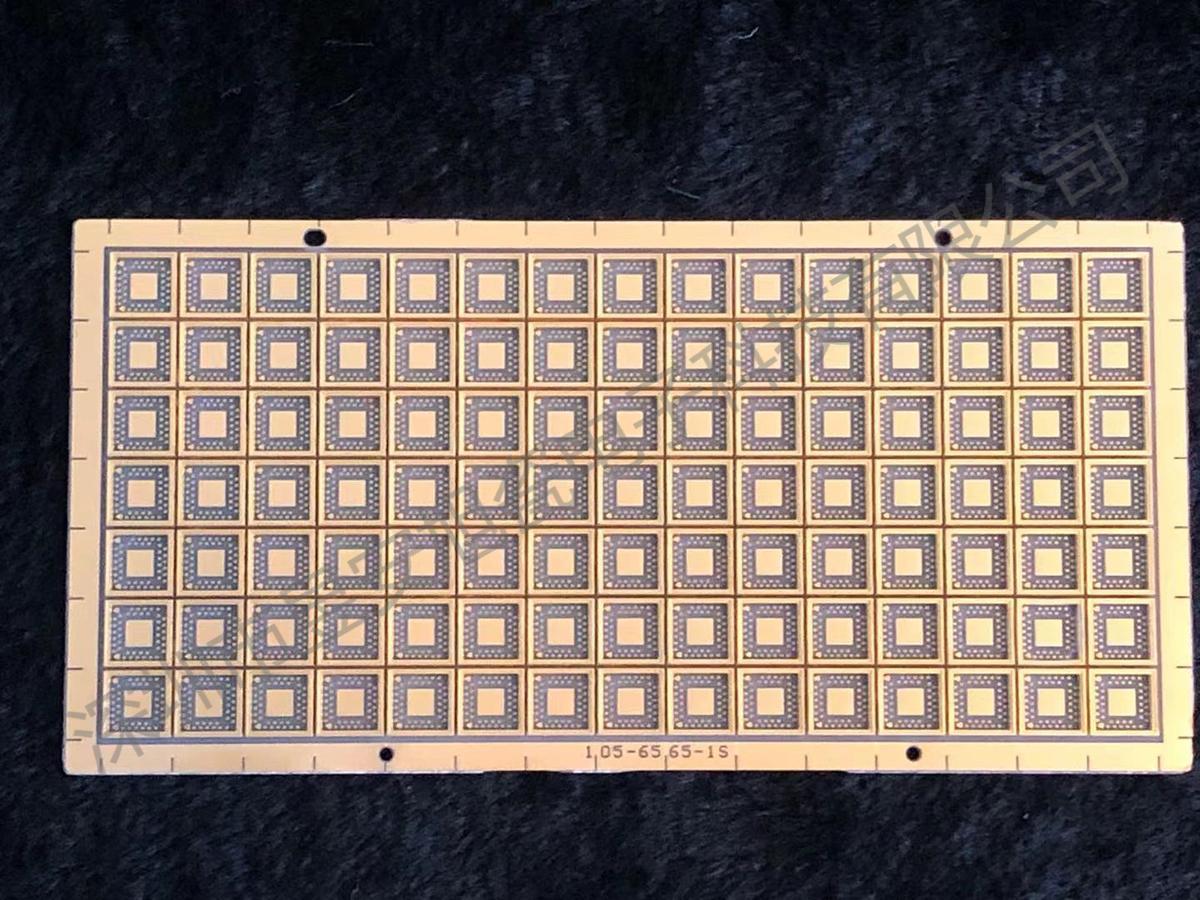

Introduction to ceramic substrate

2021-12-21 09:36:12

Ceramic substrate refers to the DPC process to bond copper to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single or double) on the special process plate. The ultra-thin composite substrate has excellent electrical insulation, high thermal conductivity, excellent soft brazing and high adhesion strength, and can be etched like PCB board, has a great current-carrying capacity. Therefore, ceramic substrate has become the basic material of high power electronic circuit structure technology and interconnection technology.

use

High power semiconductor module; Semiconductor refrigerator, electronic heater; Power control circuit, power hybrid circuit.

◆ Intelligent power module; High frequency switching power supply, solid state relay.

Automotive electronics, aerospace and military electronics components.

Solar panel module; Telecommunications private exchange, receiving system; Laser and other industrial electronics.

The characteristics of

◆ Strong mechanical stress, stable shape; High strength, high thermal conductivity, high insulation; Strong binding force, corrosion resistance.

Excellent thermal cycle performance, cycle times up to 50,000 times, high reliability.

The same as PCB board (or IMS substrate) can etch the structure of various graphics; No pollution and pollution-free.

◆ Wide operating temperature -55℃~850℃; The thermal expansion coefficient is close to silicon, simplifying the production process of power module.

superiority

◆ The thermal expansion coefficient of ceramic substrate is close to silicon chip, which can save the transition layer Mo sheet, save labor, save material and reduce cost;

Reduce welding layer, reduce thermal resistance, reduce cavity, improve the rate of finished product;

◆ The line width of 0.3mm thick copper foil is only 10% of that of ordinary printed circuit board under the same current-carrying capacity;

◆ Excellent thermal conductivity, so that the chip package is very compact, so that the power density is greatly improved, improve the reliability of the system and device;

Ultra-thin (0.25mm) ceramic substrate can replace BeO, no environmental toxicity problem;

◆ Large current, 100A current continuously through 1mm wide 0.3mm thick copper body, temperature rise of about 17℃; 100A current continuously through 2mm wide 0.3mm thick copper body, the temperature rise is only about 5℃;

◆ Low thermal resistance, the thermal resistance of 0.63mm thickness of 10×10mm ceramic substrate is 0.31K/W, 0.38mm thickness of ceramic substrate is 0.19K/W, 0.25mm thickness of ceramic substrate is 0.14K/W.

◆ High insulation and pressure resistance, ensure personal safety and equipment protection ability.

New packaging and assembly methods can be realized to make products highly integrated and small in size.

The performance requirements

(1) Mechanical properties

It has high enough mechanical strength to be used as a supporting component in addition to carrying components; Good machinability, high dimensional accuracy; Easy to achieve multi-layer;

Smooth surface, no warping, bending, microcrack, etc.

(2) Electrical properties

High insulation resistance and insulation failure voltage;

Low dielectric constant;

Low dielectric loss;

Stable performance under high temperature and high humidity to ensure reliability.

(3) Thermal properties

High thermal conductivity;

The coefficient of thermal expansion should be matched with related materials (especially with Si);

Excellent heat resistance.

(4) Other properties

Good chemical stability; Easy to metallize, strong adhesion to circuit graphics;

No hygroscopicity; Oil and chemical resistance; A ray emission is small;

The substance used is harmless and non-toxic; The crystal structure does not change in the temperature range;

Abundant raw materials; Mature technology; Easy to manufacture; The price is low.

trend

Ceramic substrate products come out, open the development of heat dissipation application industry, due to the heat dissipation characteristics of ceramic substrate, and ceramic substrate has high heat dissipation, low thermal resistance, long life, voltage resistance and other advantages, with the improvement of production technology and equipment, product price accelerated rationalization, and expand the application field of LED industry, If the indicator light of home appliance product, car lamp, street lamp and outdoor large kanban. The successful development of ceramic substrate will become indoor lighting and outdoor lighting products to provide services, so that the future LED industry market wider.