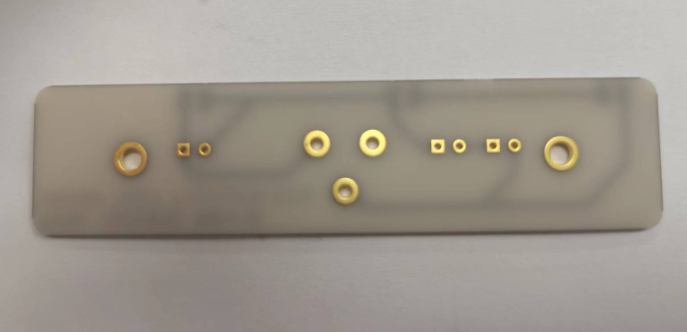

Ceramic PCB

2022-04-24 10:25:47

With the development and progress of science and technology in China, technology is constantly updated, and the stability of high power and performance. The demand for PCB is getting higher and higher. As a new type of electronic packaging substrate materials, high thermal conductivity ceramic materials are emerging in response to market demand. Packaging PCB is an important link to connect the internal and external heat dissipation channel, and has the functions of heat dissipation channel, circuit connection and physical support for the chip. Ceramic PCB with its excellent performance and gradually reduced price, in many electronic packaging materials show a strong competitiveness, is the future power chip packaging development trend.

For high power products, the packaging substrate requires high electrical insulation, high thermal conductivity, matching with the chip thermal expansion coefficient and other characteristics. The use of ceramic circuit board can effectively prolong the life of the product, save space, do the miniaturization of the product, energy saving and environmental protection is also a major advantage of ceramic substrate, now used in the market is more common alumina (Al2O3) ceramics, aluminum nitride (AlN) ceramics.

Alumina (Al2O3) ceramics are white, thermal conductivity is 20 W/(M-K) 30 W/(mK), thermal expansion coefficient is 7.0 x 10-6/°C ~8.0 x 10-6/°C in the temperature range of 25°C~200°C, elastic modulus is about 300 GPa, The bending strength is 300 MPa 400 MPa, dielectric constant is 10, alumina ceramics has the advantages of abundant raw materials, low price, high insulation, heat shock resistance, chemical corrosion resistance and high mechanical strength, is a kind of ceramic substrate material with good comprehensive performance, accounting for more than 80% of the total ceramic substrate material. However, due to its relatively low thermal conductivity (99% alumina thermal conductivity is about 30 W/ (m-K), high thermal expansion coefficient, generally used in automotive electronics, semiconductor lighting, electrical equipment and other fields.

Aluminum nitride (AlN) ceramics have excellent thermal, electrical and mechanical properties. Aluminum nitride material is gray white, the theoretical thermal conductivity of ceramic can reach 170 W/ (mK), the thermal expansion coefficient of 25°C ~200°C is 4 x 10-6/°C (with Si and GaAs semiconductor chip materials basic match), the elastic modulus of 310GPa, bending strength of 400MPa~450MPa, Dielectric constant is 8~10. Roughness is less than 0.3um, warpage is less than 2.0Length‰ breakdown strength is greater than 17KV/MM. The thermal conductivity of aluminum nitride ceramics is 6~8 times that of alumina ceramics, but the thermal expansion coefficient is only 50%. In addition, it also has the advantages of high insulation strength, low dielectric constant and good corrosion resistance. In addition to the high cost, the comprehensive performance of aluminum nitride ceramics is better than alumina ceramics, which is a very ideal substrate material for electronic packaging.

The development of intelligent science and technology in society can not be separated from the hardware support, the input of ceramic PCB will completely solve the problem of chip heat. Ceramic PCB can solve the high heat, high frequency and low resistance of chip package. For the stable performance of chip packaging to solve worries.